- TREATING CAPACITY OF FULL-LINE CONTINUOUS METHANOL & TOLUENE CARBURIZING QUENCHING FURNACE

- CRUCIBLE DRIP FEED TYPE GAS CARBURIZING FURNACE

- BOX TEMPERING FURNACE

- NON OXIDATION BRIGHT ANNEALING FURNACE

- CONTINUOUS HOT BLAST NON-OXIDATION ANNEALING BRIGHT ANNEALING FURNACE

- CONTINUOUS NORMALIZING FURNACE

- GAS NITRIDING FURNACE

- INGOT FURNACE

- AGING FURNACE

- CONTINUOUS HIGH TEMPERATURE FURNACE

- PHOSPHORUS REMOVAL EQUIPMENT

- SOLID SOLUTION FURNACE

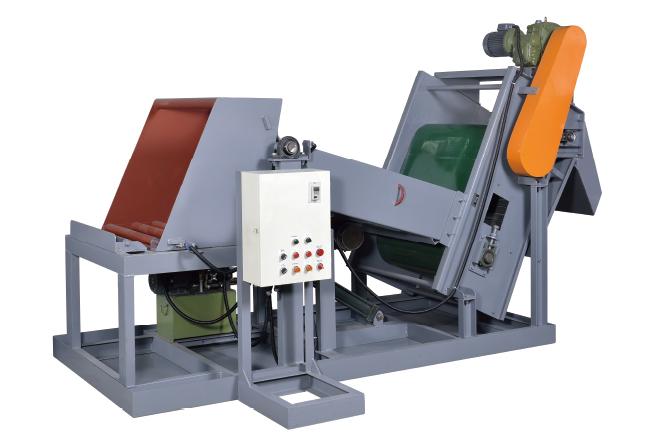

MAGNETIC CONVERYOR

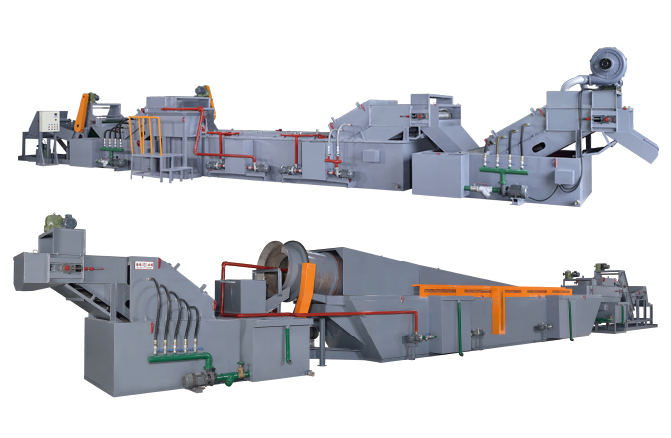

Applications:

■ For transmission of small parts to degreasing and washing unit.

■ For transmission of small parts to degreasing and washing unit.

■ To assure the even dispersion of small parts during transmitting before entering

the furnace for heat treatment.

the furnace for heat treatment.

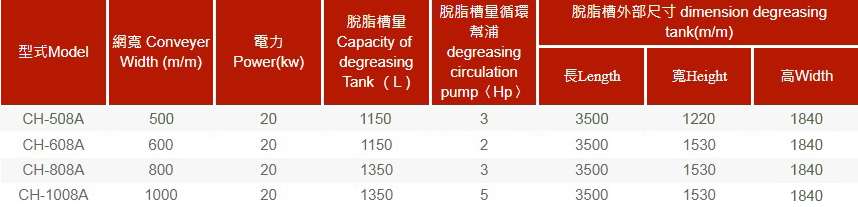

FRONT DEGREASING AND WASHING UNIT

■ A preheating device is installed in the furnace to provide adequate amount of hot water to save energy.

■ Equipped with oil/water segregator and blow dryer.

■ Application:To remove and wash off greating parts.

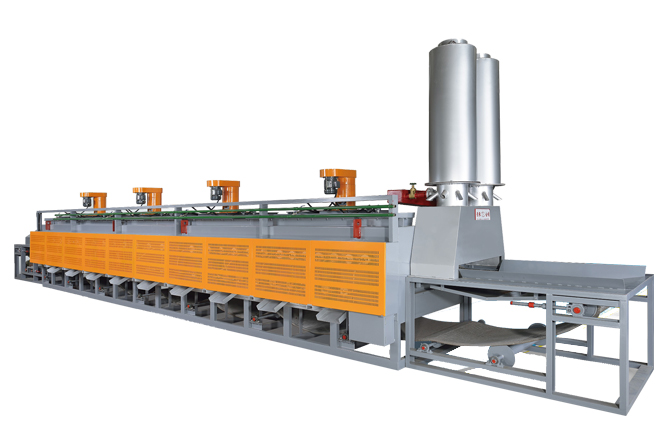

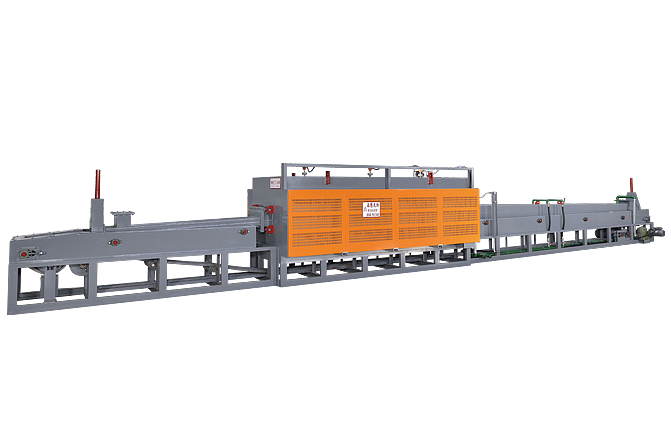

CONTINUOUS CARBURIZING QUENCHING FURNACE

■ Power: Use light weight, high strength, high insulation insulation materials, electric reach maximum efficiency.

■ Operation: Automatic control operation, no people to operate, saving manpower.

■ Quality: Adopt multi-point control, temperature uniformity and improve quality.

■ Furnace gas: Can be turned into the furnace type, or mixed with other gases, high selectivity, furnace gas stability

and ensure quality.

and ensure quality.

■ Maintenance: The mesh belt conveyor, smooth operation, easy to fall into the furnace treated to reduce the failure rate,

most of the group from time to shutdown replacement parts, convenient maintenance.

most of the group from time to shutdown replacement parts, convenient maintenance.

■ Uses: mechanical parts, carburizing quenching hardware, tools (maximum processing temperature of 920°C)

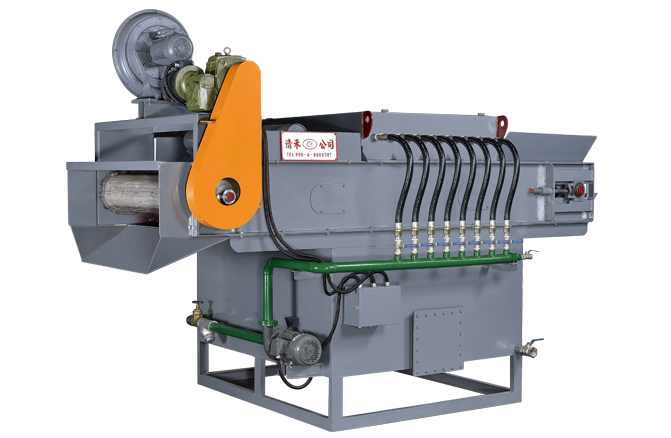

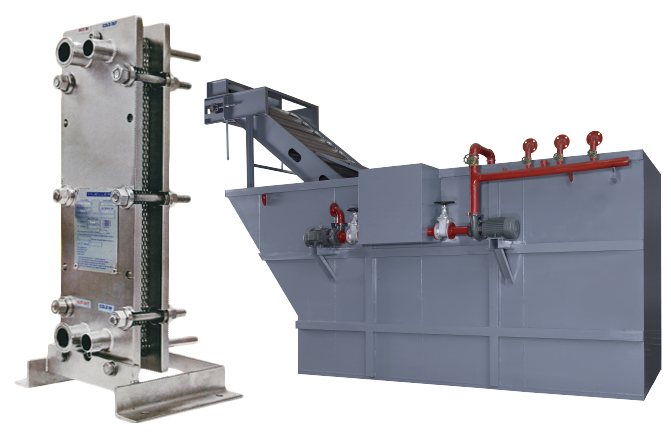

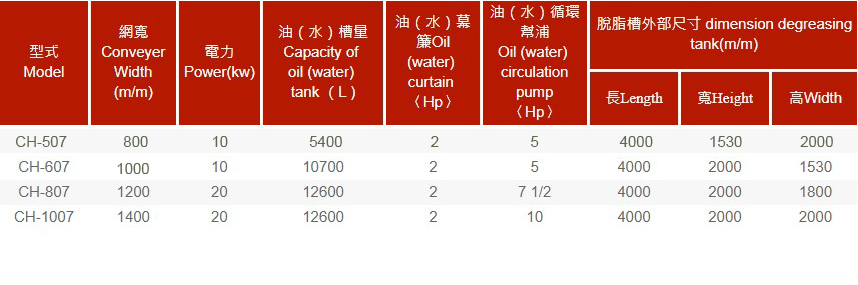

QUENCHING COOLING OIL TANK

■ Equipped with the high-efficiency cool/hot exchanger to monitor and rapidly adjust the temperature of oil (water).

The temperature is maintained at 60°c-80°c for oil.

The temperature is maintained at 60°c-80°c for oil.

■ The speed of sprinkle water is adjusted accordingly by the sprinkle-water cooling system to produce desired volumes

of water as needed by treating parts in terms of their size ariations.

of water as needed by treating parts in terms of their size ariations.

■ Installed in the tank, the filter will fend off accumulation of particles occurred during heat treating, and thus maximize

the effect of the cooling tank. The filter is easy to clean and replace.

the effect of the cooling tank. The filter is easy to clean and replace.

■ Application:to maintain cooiling oil﹙water﹚in desired of temperature to ensure the quality parts.

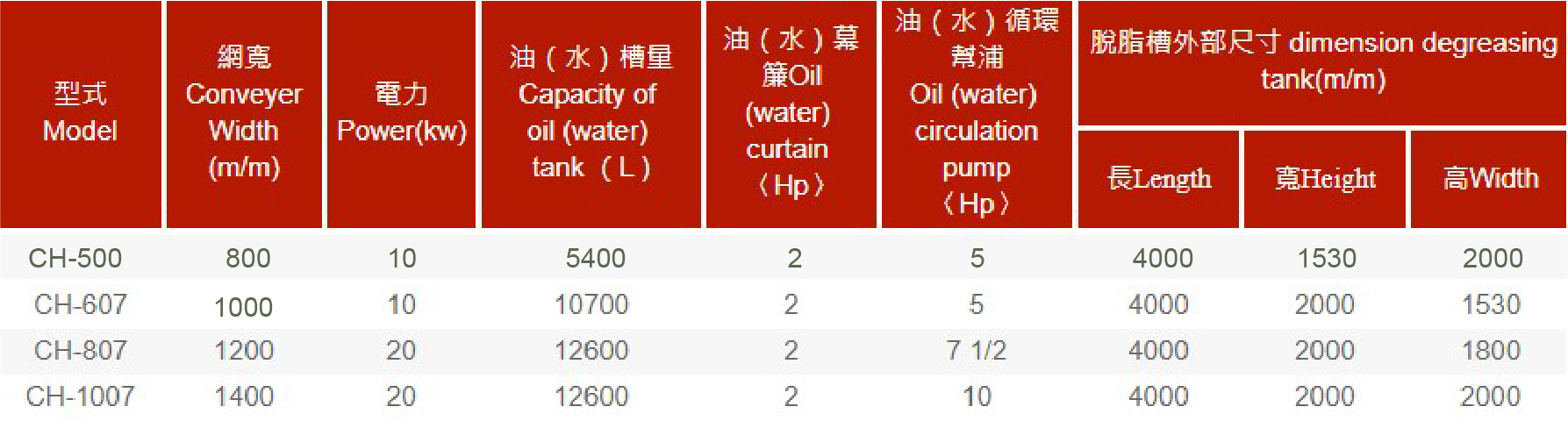

REAR DEGREASING & WASHING TANK

■ A preheating device is installed in the furnace to provide adequate amount of hot water to save energy.

■ Equipped with oil/water segregator and blow dryer.

■ Application:To remove and wash off greating parts.

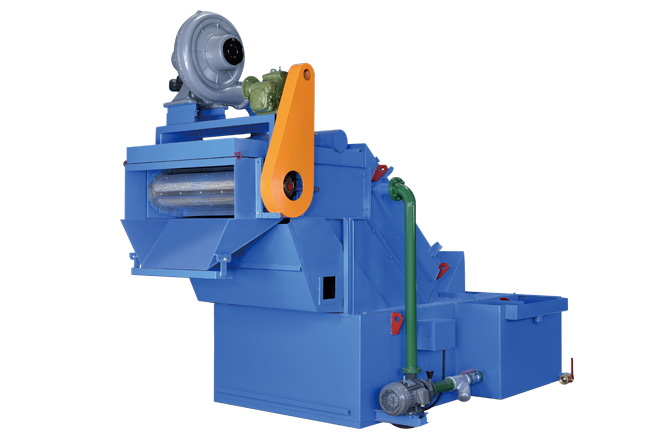

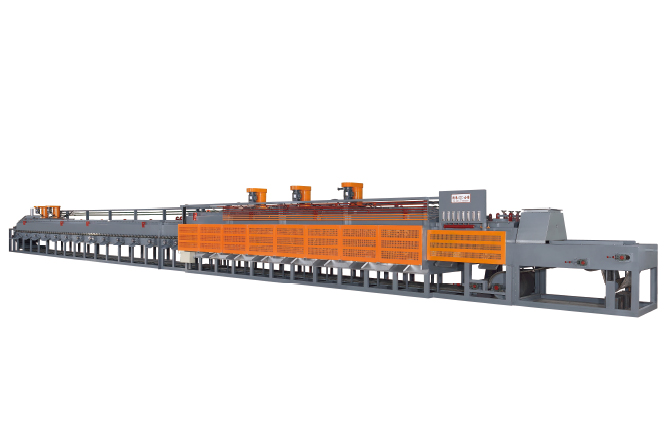

CONTINUOUS HOT BLAST TEMPERING FURNACECONTINUOUS HOT BLAST TEMPERING FURNACE

■ The top-bottom design of the heater will keep the temperature in uniform and extend the

service life of the furnace with lower possibilities of malfunction.

service life of the furnace with lower possibilities of malfunction.

■ The stirring fan is installed to maintain constant temperature in furnace and keep consistant

hardness in treating parts.

hardness in treating parts.

■ Application: Toprocess hardware, tools and other mechanic parts.

﹙Maximum operation temp. 650℃﹚

﹙Maximum operation temp. 650℃﹚

AUTOMATIC TEMPERATURE CONTROL PANEL

■ The integration of temperature and atmosphere control offers easier operation.

■ The adoption of scr in temperature control will assure the accuracy of temperature and timing.

■ Aassembled with heat resistant instrumental panels to ensure the quality of treating parts.

■ Top-quality components are used to increase the reliability of the system.

■ Application: to control temperature and atmosphere in the furnace.

O2 AUTOMATIC CARBON POTENTUAL CONTROL SYSTEM

■ To control atmosphere in the furnace.

■ O2 SENSOR

1. Continuous Sensing of % Carbon in furnace

2. Stabilized Zirconlum oxide element

3. One second responsse time from %carbon sensor

4. Accurate at very low oxygen partial pressures

5. Operates up to 2000℉ (1093℃)

6. Minimum sooting

O2碳濃度控制系統(1點式)

HOT AIR FURNACE CRUCIBLE

Uses:

Part crucible after instillation gas quenching furnace hardened using hot crucible furnace is set to the desired temperature tempering operations to achieve the desired target hardness.

CRUCIBLE DRIP GAS QUENCHING FURNACE

Uses:

1.quenching types of machinery parts, carburizing, hardening heat treatment.

2.hardened spindles and gears class deep carburizing layer.

3.After forging the way various parts of the annealing heat treatment.

4.Various softening heat treatment of steel.

QUENCHING COOLING OIL TANK

■Purpose:

After part in the crucible drip gas quenching furnace heating is completed, the rapid quenching hanging into the tank, quenching, to achieve the hardness required.

脫脂洗淨槽

用途:

零件於淬火槽淬火後清洗附著於工件表面的油脂

O2碳濃度控制系統

AUTOMATIC TEMPERATURE CONTROL PANEL

■Purpose:

Controls the crucible drip gas quenching furnace and hot air furnace crucible in the production process of the job required temperature and time.

■ Purpose

After quenching hard quenching, tempering treatment can reducing brittleness improve toughness

required to meet the performance requirements

required to meet the performance requirements

■ Purpose

When the workpiece annealing operations , the surface remain brightness conditions.

■ Purpose:

Forging, casting parts annealing

■ Purpose

To adjust the grain size of hot forging parts , the workpiece to stress relief treatment.

■ Purpose

1.Carburizing, nitriding heat treatment of all types of machinery parts.

2.Processing mandrels and Gear shallow nitride layer.

3.After forging the way various parts of the annealing heat treatment.

4.Various softening heat treatment of steel.

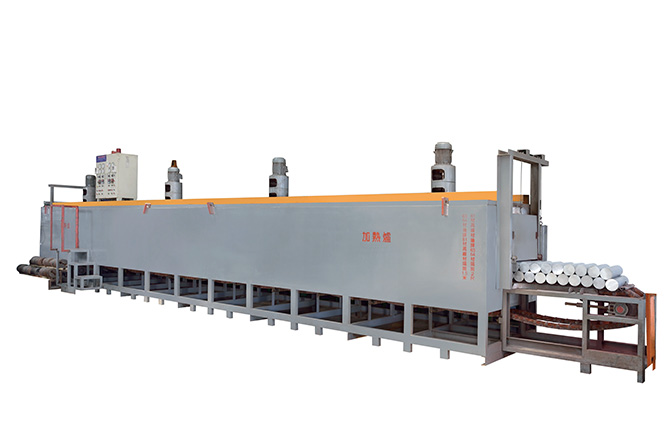

■ Purpose

All kinds of aluminum extrusion ingots heating before forming.

■ Purpose

All kinds of aluminum products perform artificial age hardening heating.

■ Purpose

All kinds of high temperature furnace for the continuity of the workpiece moves.

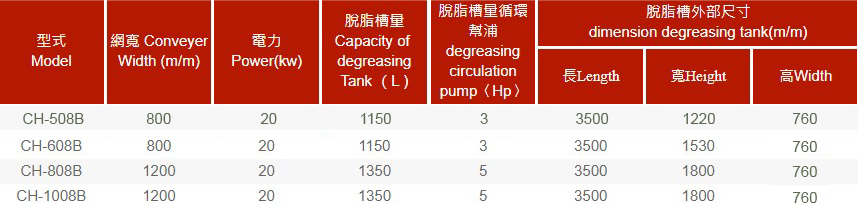

■ Purpose:

Phosphorus Removal purpose: for high strength screws and phosphorus, to reduce the brittleness.

Phosphorus Removal purpose: for high strength screws and phosphorus, to reduce the brittleness.

■ 瓦斯控制保護系統,安全耐用,露點控制穩定,操作簡單,指示精確,並且與CO2控制器聯結使用,

達到自動控制的目標。

■ 發熱氣體效率高,故障率低。爐室可以打開,便於保養與修護。

■ 流量計及瓦斯開關都裝配在操作面板上,操作、控制及檢查均方便。

■ 管路設計預留清除雜物接頭,便於清除雜物。

■ 用途:將瓦斯經觸媒分解成RX氣體,作為淬火爐的處理物的保護氣體。